2 月 . 10, 2025 11:41

Back to list

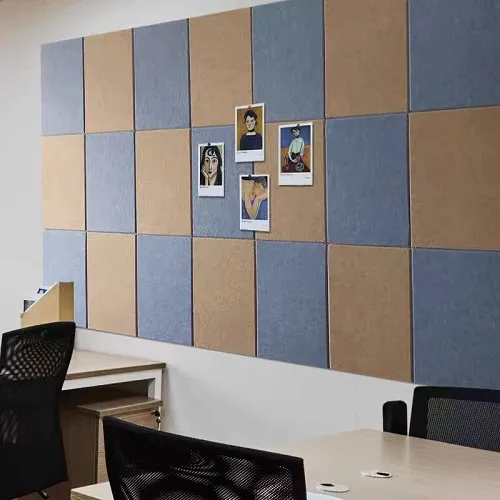

industrial felt products

Industrial felt products have become a cornerstone in various industrial applications, providing versatile solutions for a range of challenges. As a practiced professional in the field, I have experienced firsthand the significant impact these products have across industries. Their functionality and reliability are not just a testament to their technological advancement, but also to the expertise and trustworthiness embedded in their manufacture and use.

Moreover, advancements in manufacturing technologies have continued to elevate the quality and effectiveness of industrial felt products. Precision cutting techniques and enhanced binding processes have improved the dimensional stability and overall integrity of felt products, ensuring that they meet rigorous industrial standards. Trust in these products is also reflected in their compliance with global industry standards. Reputable manufacturers adhere to stringent quality control procedures and certifications, such as ISO standards, which not only guarantee product reliability but also affirm their commitment to maintaining industry-quality benchmarks. Real-world applications underscore the authority of industrial felt products. For instance, in the textile industry, felt is used as a pressing cushion, which demonstrates its ability to withstand high temperatures and pressures while providing a consistent surface for fabric treatment. Meanwhile, in metalworking, felt polishing wheels are praised for their precision in delivering a high-quality finish without damaging underlying materials, showcasing felt’s gentle yet effective abrasion qualities. In conclusion, industrial felt products are indispensable due to their tailored material options, advanced manufacturing processes, and compliance with global industry standards. Their versatile applications across numerous industries not only highlight their functional performance but also cement their place as reliable assets in industrial operations. As industries continue to evolve and new challenges arise, the expertise in industrial felt products ensures that they will continue to innovate and adapt, providing trustworthy solutions that meet the demanding needs of modern industrial environments.

Moreover, advancements in manufacturing technologies have continued to elevate the quality and effectiveness of industrial felt products. Precision cutting techniques and enhanced binding processes have improved the dimensional stability and overall integrity of felt products, ensuring that they meet rigorous industrial standards. Trust in these products is also reflected in their compliance with global industry standards. Reputable manufacturers adhere to stringent quality control procedures and certifications, such as ISO standards, which not only guarantee product reliability but also affirm their commitment to maintaining industry-quality benchmarks. Real-world applications underscore the authority of industrial felt products. For instance, in the textile industry, felt is used as a pressing cushion, which demonstrates its ability to withstand high temperatures and pressures while providing a consistent surface for fabric treatment. Meanwhile, in metalworking, felt polishing wheels are praised for their precision in delivering a high-quality finish without damaging underlying materials, showcasing felt’s gentle yet effective abrasion qualities. In conclusion, industrial felt products are indispensable due to their tailored material options, advanced manufacturing processes, and compliance with global industry standards. Their versatile applications across numerous industries not only highlight their functional performance but also cement their place as reliable assets in industrial operations. As industries continue to evolve and new challenges arise, the expertise in industrial felt products ensures that they will continue to innovate and adapt, providing trustworthy solutions that meet the demanding needs of modern industrial environments.

Next:

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024