2 月 . 10, 2025 11:36

Back to list

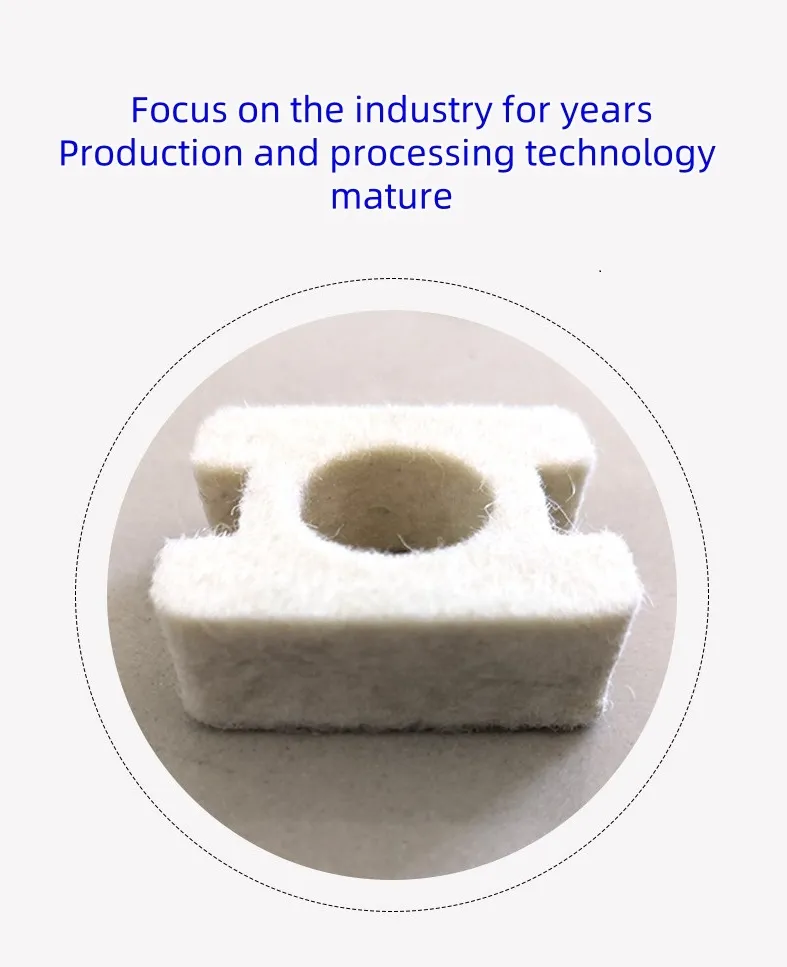

machinery felt

Machinery felt, often dubbed the unsung hero in industrial processes, is a pivotal component leveraged across numerous manufacturing sectors. Its applications, rooted in historical use but constantly evolving, mark a blend of tradition with innovation—mirroring the delicate balance factories strive to achieve between technology and tactile materials.

In recent years, the evolution of machinery felt has been marked by advancements in material science. These developments have ushered in the production of specialty felts, tailored to meet the precise needs of specific industries. For example, antistatic felts are now commonly used in electronics manufacturing to prevent electromagnetic interference, a testament to the felt’s versatility and the innovative application of its intrinsic properties. Authoritative voices in machinery felt production emphasize precise engineering in design, along with rigorous testing to ensure each batch fulfills its intended purpose. Collaborations between material scientists and industrial engineers have been pivotal in refining the felt’s properties, ensuring it meets the unique demands of each application. Ultimately, machinery felt’s significance lies in its adaptability—a melding of historical craftsmanship with cutting-edge technology. In manufacturing environments where quality, precision, and dependability are non-negotiable, machinery felt remains an invaluable resource. Its involvement in these sectors not only guarantees meticulous operations but also serves as a testament to the sophisticated blend of expertise and reliability that drives modern industry forward. By aligning its attributes with evolving industrial requirements, machinery felt continually reaffirms its relevance, positioning itself as an indispensable element in the machinery of progress. As industries continue seeking solutions that offer both traditional robustness and modern adaptability, machinery felt stands poised to bridge the gap seamlessly.

In recent years, the evolution of machinery felt has been marked by advancements in material science. These developments have ushered in the production of specialty felts, tailored to meet the precise needs of specific industries. For example, antistatic felts are now commonly used in electronics manufacturing to prevent electromagnetic interference, a testament to the felt’s versatility and the innovative application of its intrinsic properties. Authoritative voices in machinery felt production emphasize precise engineering in design, along with rigorous testing to ensure each batch fulfills its intended purpose. Collaborations between material scientists and industrial engineers have been pivotal in refining the felt’s properties, ensuring it meets the unique demands of each application. Ultimately, machinery felt’s significance lies in its adaptability—a melding of historical craftsmanship with cutting-edge technology. In manufacturing environments where quality, precision, and dependability are non-negotiable, machinery felt remains an invaluable resource. Its involvement in these sectors not only guarantees meticulous operations but also serves as a testament to the sophisticated blend of expertise and reliability that drives modern industry forward. By aligning its attributes with evolving industrial requirements, machinery felt continually reaffirms its relevance, positioning itself as an indispensable element in the machinery of progress. As industries continue seeking solutions that offer both traditional robustness and modern adaptability, machinery felt stands poised to bridge the gap seamlessly.

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024