2 月 . 13, 2025 05:45

Back to list

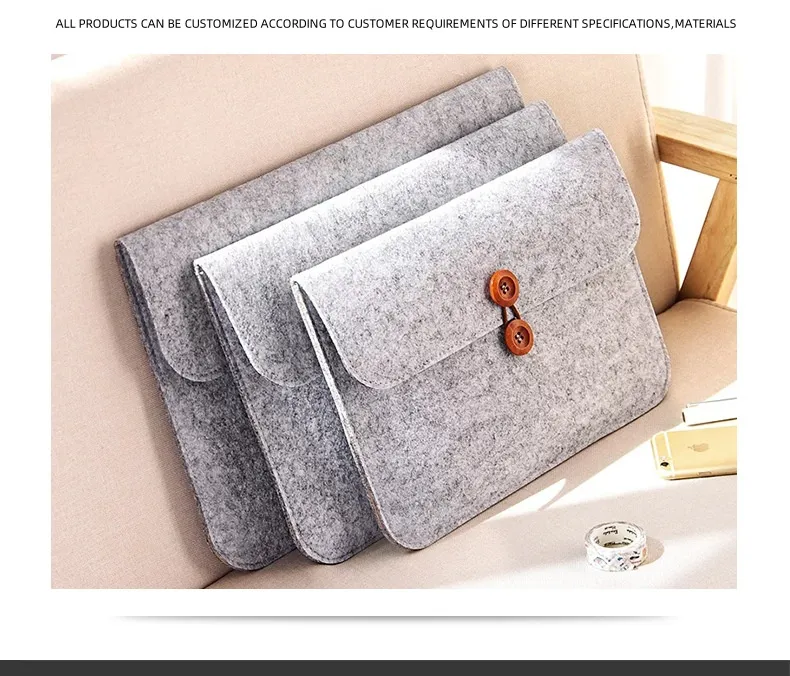

felt pet house

Wool felt polishing wheels have become indispensable tools across various industries, valued for their efficiency and reliability in achieving a high-quality finish on a multitude of surfaces. These tools are employed particularly in precision fields where even the minutest surface irregularity can impact product quality significantly.

Expertise in the effective use of wool felt polishing wheels encompasses understanding the compatibility of polishing compounds with the wheel. Different compounds can be used depending on the desired level of polish and material being worked on. For instance, a coarser compound is ideal for initial polishing stages where material removal is essential, while finer compounds are used for shine and luster in the final stages. Authoritativeness in the choice and application of these wheels is paramount. Industrial manufacturers often recommend regular dressing of the wheels to maintain their shape and effectiveness. Additionally, expertise in maintaining optimal rotation speeds for different materials can maximize polishing outcomes while minimizing wheel wear. This data-driven approach is crucial in high-stakes environments like aerospace manufacturing where surface integrity is non-negotiable. Trustworthiness in product quality can be increased by sourcing wheels from reputed manufacturers who adhere to international standards. Look for brands that provide transparency in the composition of their wheels and offer data-supported performance metrics. Reputable brands often have documented testing methods for their wheels, assuring users of consistent performance under specified conditions. In summary, wool felt polishing wheels are not just another tool in an industrial toolkit—they are precision instruments fundamental to achieving a sublime finish without compromising on material integrity. Their unique composition and versatile application make them critical in various sectors. It is the blend of expertise, proper application, and quality assurance that distinguishes a good polishing job from a great one. Embracing these facets ensures that your use of wool felt polishing wheels aligns with best practices, thereby securing optimal results in your professional endeavors.

Expertise in the effective use of wool felt polishing wheels encompasses understanding the compatibility of polishing compounds with the wheel. Different compounds can be used depending on the desired level of polish and material being worked on. For instance, a coarser compound is ideal for initial polishing stages where material removal is essential, while finer compounds are used for shine and luster in the final stages. Authoritativeness in the choice and application of these wheels is paramount. Industrial manufacturers often recommend regular dressing of the wheels to maintain their shape and effectiveness. Additionally, expertise in maintaining optimal rotation speeds for different materials can maximize polishing outcomes while minimizing wheel wear. This data-driven approach is crucial in high-stakes environments like aerospace manufacturing where surface integrity is non-negotiable. Trustworthiness in product quality can be increased by sourcing wheels from reputed manufacturers who adhere to international standards. Look for brands that provide transparency in the composition of their wheels and offer data-supported performance metrics. Reputable brands often have documented testing methods for their wheels, assuring users of consistent performance under specified conditions. In summary, wool felt polishing wheels are not just another tool in an industrial toolkit—they are precision instruments fundamental to achieving a sublime finish without compromising on material integrity. Their unique composition and versatile application make them critical in various sectors. It is the blend of expertise, proper application, and quality assurance that distinguishes a good polishing job from a great one. Embracing these facets ensures that your use of wool felt polishing wheels aligns with best practices, thereby securing optimal results in your professional endeavors.

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024