1 月 . 15, 2025 09:13

Back to list

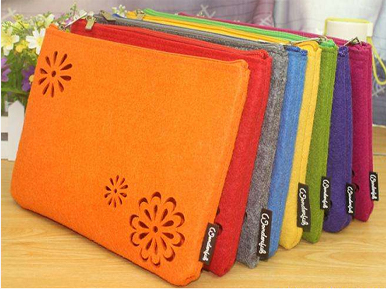

Felt Shopping Bag\Gift Bag

Felt, an ancient fabric with a modern twist, continues to capture the imagination of crafters, designers, and industrial innovators alike. Known for its versatility, durability, and tactile appeal, felt is used in a myriad of applications ranging from fashion to industrial engineering. Understanding the different types of felt available in the market today is crucial for both hobbyists and professionals seeking to harness its unique properties for their specific needs.

Technical felt, a category often overlooked by consumers, is engineered for specialized industrial uses. This type of felt is used in machinery, automotive, and acoustic settings due to its precise specifications tailored for impact absorption, soundproofing, and filtration. It withstands heavy-duty applications and offers long-term performance under strenuous conditions, ensuring that automotive and aerospace industries frequently rely on it as a material solution. Additionally, needle felt stands out as a non-woven fabric formed through mechanical entanglement using barbed needles. Its production does not require heat or an adhesive, making it an environmentally friendly option. Known for its excellent filtration properties, needle felt is prevalent in the production of air and liquid filters, as well as applications requiring sturdy, resilient materials. Finally, press felt, which is barely known outside the specialized paper production sphere, is vital for ensuring the quality of paper manufacturing. Engineered to exacting standards, press felt aids in water removal and improves the surface finish during the paper-making process, highlighting its importance in industrial settings. In summary, the wide range of felt types available today caters to a diverse array of applications, from traditional crafts to cutting-edge industrial innovations. Each type possesses unique qualities that render it suitable for specific uses, emphasizing the importance of selecting the right felt to meet the demands of one's project. By understanding these differences, consumers, designers, and engineers can enhance their projects’ outcomes, ensuring that felt continues to be a cornerstone material across industries.

Technical felt, a category often overlooked by consumers, is engineered for specialized industrial uses. This type of felt is used in machinery, automotive, and acoustic settings due to its precise specifications tailored for impact absorption, soundproofing, and filtration. It withstands heavy-duty applications and offers long-term performance under strenuous conditions, ensuring that automotive and aerospace industries frequently rely on it as a material solution. Additionally, needle felt stands out as a non-woven fabric formed through mechanical entanglement using barbed needles. Its production does not require heat or an adhesive, making it an environmentally friendly option. Known for its excellent filtration properties, needle felt is prevalent in the production of air and liquid filters, as well as applications requiring sturdy, resilient materials. Finally, press felt, which is barely known outside the specialized paper production sphere, is vital for ensuring the quality of paper manufacturing. Engineered to exacting standards, press felt aids in water removal and improves the surface finish during the paper-making process, highlighting its importance in industrial settings. In summary, the wide range of felt types available today caters to a diverse array of applications, from traditional crafts to cutting-edge industrial innovations. Each type possesses unique qualities that render it suitable for specific uses, emphasizing the importance of selecting the right felt to meet the demands of one's project. By understanding these differences, consumers, designers, and engineers can enhance their projects’ outcomes, ensuring that felt continues to be a cornerstone material across industries.

Next:

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024