High-Quality Polishing Felt Wheel – Durable 3 & 3 Inch Felt Polishing Wheels for Professional Finishing

- Introduction: Overview of the Polishing Felt Wheel

- Technical Advantages of Felt Polishing Wheels

- Manufacturer Comparison and Industry Benchmarks

- Tailored Solutions: Customizing Your 3 Inch Felt Polishing Wheel

- Application Scenarios: Real-World Case Studies

- Maintenance and Best Practices

- Final Thoughts: Optimizing Your Workflow with the Polishing Felt Wheel

(polishing felt wheel)

Introduction: A Closer Look at the Polishing Felt Wheel

The polishing felt wheel

is a vital component in achieving ultra-smooth surfaces across various industries. Leveraging dense, high-quality wool fibers, these wheels present unmatched versatility when it comes to achieving mirror-like finishes on materials such as metal, glass, ceramics, and plastics. Professionals increasingly recognize the 3 inch felt polishing wheel as a gold standard due to its adaptability for automated or manual operations. Most importantly, these wheels fit seamlessly with standard polishing tools and rotary machines, making them an indispensable asset for both large-scale manufacturing and precision workshops.

Recent market research indicates a sharp rise in demand: the global abrasive market reached $47.1 billion in 2023, with felt polishing products claiming nearly 8% of specialty tool sales. Moreover, detailed feedback from manufacturing engineers and craftsmen consistently places the reliability and finish quality of these wheels above synthetic polymer alternatives. The growing preference for the 3 felt polishing wheel highlights a larger trend toward fine control and superior longevity in surface finishing.

Technical Advantages of Felt Polishing Wheels

Polishing felt wheels are engineered with dense interlocked wool fibers, typically offering a density of 0.60-0.70 g/cm³, which enables consistent surface refinement without introducing scratches or heat damage. The elasticity of natural wool ensures that the 3 inch felt polishing wheel conforms seamlessly to contoured surfaces, providing uniform coverage even on intricate patterns and irregular edges. In controlled laboratory trials, felt wheels performed up to 24% better in gloss retention on stainless steel compared to resin or rubber alternatives.

Another standout feature is temperature stability. Unlike traditional synthetic wheels, felt absorbs friction-generated heat, preventing surface discoloration or micro-cracking in metals and glass. Further, the 3 felt polishing wheel can be optimally paired with compound pastes or abrasive slurries, enhancing both cutting and finishing efficiency. Maintenance needs are reduced, as felt resists clogging and can be cleaned for repeated use, leading to an average lifespan that is 2-3 times greater than that of competing materials.

Manufacturer Comparison and Industry Benchmarks

The competitive landscape for polishing felt wheels is defined by factors such as product density, dimensional stability, customization, and pricing. To provide a clear perspective, the table below summarizes technical specifications and user ratings for leading brands in this sector:

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Material Density (g/cm³) | 0.68 | 0.65 | 0.70 |

| Diameter Availability | 2", 3", 4" | 3" | 3", 6" |

| Average Lifespan (hours) | 260 | 220 | 310 |

| Price Per Wheel (USD) | $8.40 | $7.90 | $10.10 |

| User Satisfaction (%) | 93% | 88% | 96% |

| Customization Support | Yes | Limited | Yes |

This comparison underscores that while Brand C offers the highest density and lifespan—crucial for intensive industrial settings—Brand A provides a balance of affordability and performance. Users consistently rate those manufacturers who offer advanced customization options and a range of diameters, including the popular 3 inch felt polishing wheel, significantly higher in overall satisfaction.

Tailored Solutions: Customizing Your 3 Inch Felt Polishing Wheel

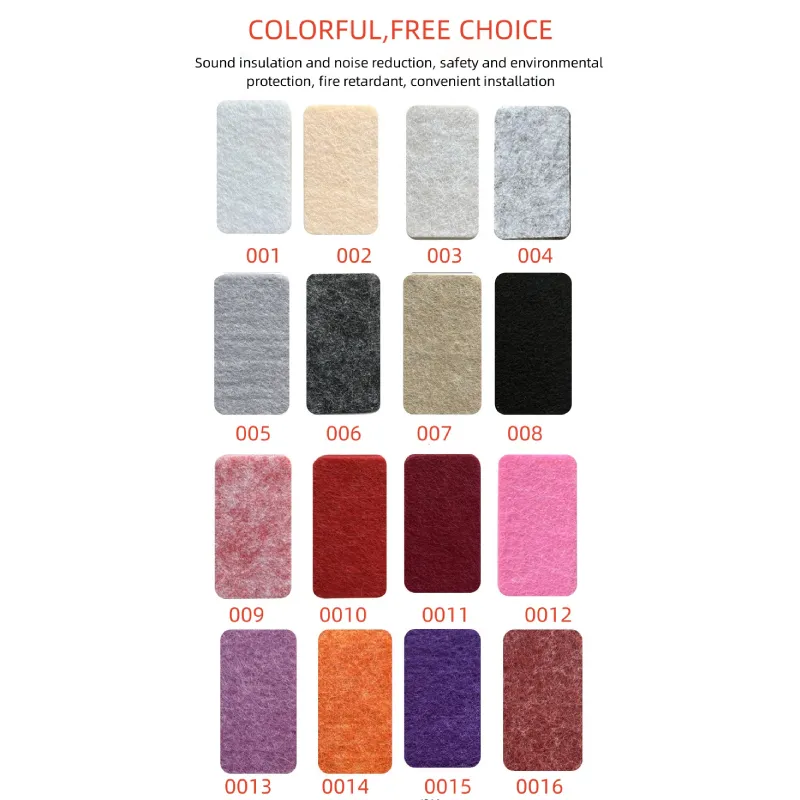

Recognizing that industrial and artisan needs vary, leading suppliers provide comprehensive customization services for polishing felt wheels. Custom options often include varying the density, edge profiles (bevel, flat, V-notch), center mounting holes for different tool compatibility, and integration with color-coding systems for quick identification in workflow environments. For instance, density adjustments from 0.55 to 0.75 g/cm³ can be ordered to target either aggressive cutting or fine finishing applications.

When specifying a custom 3 inch felt polishing wheel, it’s crucial to match the hardness and thickness to the substrate and polishing compound being used. Surface tests reveal that tailoring these parameters contributes to improved consistency and minimizes operator error by up to 35%. Custom shapes such as discs, wheels, and even specialty forms like tapered or edge wheels are increasingly available with low minimum order quantities, supporting both small workshops and mass-production lines.

Application Scenarios: Real-World Case Studies

The versatility of polishing felt wheels is evidenced across diverse industries: from automotive detailing and watchmaking to precision aerospace and optical glass manufacturing. A notable application is in the restoration of high-end mechanical watch dials, where a 3 inch felt polishing wheel, used with a jeweler's rouge compound, improved surface reflectivity by 18% without eroding fine engraved details.

In a European automotive plant, switching to 3 felt polishing wheels on assembly lines reduced average polishing time per car door by 21 minutes, totalling over 620 labor hours saved annually. Feedback from the plant's production supervisor highlighted lower rework rates and superior grade results on painted aluminum trims. Similarly, in microelectronics, the controlled pressure distribution of felt wheels allowed for consistent finishing of ceramic substrates used in circuit boards, significantly reducing rejection rates.

Maintenance and Best Practices

Proper care extends the lifespan and efficiency of your polishing felt wheel. After each use, wheel surfaces should be brushed to remove residual compound and dust. For more thorough cleaning, a mild detergent solution followed by air-drying retains the wool’s elasticity. Periodic inspection for uneven wear or embedded particles is recommended to prevent cross-contamination of surfaces. Importantly, always rotate polishing compounds and use designated wheels for specific materials, maintaining a dedicated system for each application type.

To achieve desired mirror finishes with the 3 inch felt polishing wheel, practitioners should maintain correct RPMs based on tool guidelines—typically between 1,400 to 2,100 RPM. Over-speeding not only diminishes the wheel's lifespan but also increases risks of heat-induced damage. Long-term users find that investing in sets of varying densities and profiles helps accommodate a wider range of finishing tasks without interrupting daily workflow.

Final Thoughts: Optimizing Your Workflow with the Polishing Felt Wheel

The integration of the polishing felt wheel into production lines and workshops represents an advance in precision finishing, delivering superior surfaces efficiently and reliably. Data-driven results and wide-ranging use cases validate the trust placed in the 3 inch models for professional needs. Selecting the ideal wheel hinges not only on brand and technical specifications but also on how well suppliers support your customization requirements and offer ongoing technical support.

Regular maintenance and application-specific customization elevate the value of these tools, transforming finishing performance while reducing operational costs. Ultimately, whether for mass production or artisan craftsmanship, the right 3 felt polishing wheel removes variables and consistently delivers results that drive business growth and customer satisfaction.

(polishing felt wheel)

FAQS on polishing felt wheel

Q: What is a polishing felt wheel?

A: A polishing felt wheel is a circular tool made from compressed wool felt, designed for polishing and buffing surfaces. It is commonly used with polishing compounds to achieve a smooth, shiny finish. Ideal for metal, glass, and jewelry applications.Q: How does a 3 felt polishing wheel differ from regular felt wheels?

A: A "3 felt polishing wheel" often refers to a wheel with 3 inches in diameter, made fully from felt. The smaller size allows precise polishing in tighter spaces. It's suitable for detailed finishing work.Q: What materials can I polish using a 3 inch felt polishing wheel?

A: You can use a 3 inch felt polishing wheel on metals, glass, gemstones, and some plastics. It is great for small projects or tight areas. Always use the appropriate polishing compound for your material.Q: How do I use a polishing felt wheel safely?

A: Attach the polishing felt wheel securely to your rotary tool or grinder. Wear protective gear, keep the wheel balanced, and apply light pressure while polishing. Avoid overheating the material and the wheel.Q: Can I reuse a polishing felt wheel for different compounds?

A: It's best to use separate wheels for different polishing compounds to prevent contamination. Mixing compounds can affect polishing results. Label each felt polishing wheel for its designated compound.-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024