1 月 . 15, 2025 09:35

Back to list

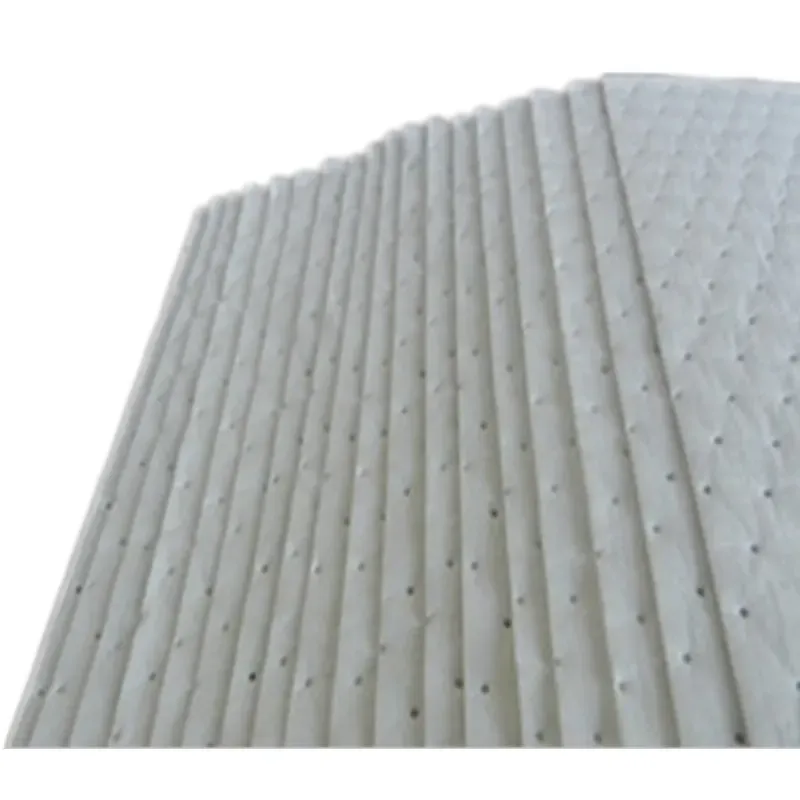

industrial felt fabric

Industrial felt fabric, a versatile and essential material, plays a crucial role in various manufacturing processes and product development. Recognized for its durability, flexibility, and unique properties, this fabric is integral to numerous industrial applications. Businesses across diverse sectors often rely on industrial felt fabric for its remarkable capacity to meet specialized needs, enhancing both product quality and functionality.

The authoritativeness of industrial felt fabric also extends to its eco-friendly characteristics. Many industrial felt products are produced from natural, biodegradable fibers, offering sustainable solutions for industries eager to lessen their environmental footprint. Additionally, manufacturing processes for felt can be energy-efficient, given that felt production typically requires less water and chemicals compared to other textile manufacturing methods. Emphasizing sustainability, businesses can reliably use industrial felt fabric without compromising on quality or performance, aligning with global trends towards greener practices. Trustworthiness in industrial felt fabric is evident through its compliance with rigorous industry standards and certifications. Companies producing industrial felt are often subjected to comprehensive quality assurance processes, ensuring that their products meet or exceed safety and quality benchmarks. This reliability in manufacturing translates to consistent product performance, allowing companies to depend on industrial felt for critical components without concern for quality variance. In conclusion, industrial felt fabric stands out as a material that embodies quality, versatility, and sustainability, catering to the demands of numerous industrial sectors. Its durability, flexibility, and specialized properties make it an invaluable resource for businesses seeking to enhance product performance and efficiency. By choosing industrial felt fabric, companies align with a tradition of excellence and innovation, ensuring they remain competitive and responsible within their respective fields.

The authoritativeness of industrial felt fabric also extends to its eco-friendly characteristics. Many industrial felt products are produced from natural, biodegradable fibers, offering sustainable solutions for industries eager to lessen their environmental footprint. Additionally, manufacturing processes for felt can be energy-efficient, given that felt production typically requires less water and chemicals compared to other textile manufacturing methods. Emphasizing sustainability, businesses can reliably use industrial felt fabric without compromising on quality or performance, aligning with global trends towards greener practices. Trustworthiness in industrial felt fabric is evident through its compliance with rigorous industry standards and certifications. Companies producing industrial felt are often subjected to comprehensive quality assurance processes, ensuring that their products meet or exceed safety and quality benchmarks. This reliability in manufacturing translates to consistent product performance, allowing companies to depend on industrial felt for critical components without concern for quality variance. In conclusion, industrial felt fabric stands out as a material that embodies quality, versatility, and sustainability, catering to the demands of numerous industrial sectors. Its durability, flexibility, and specialized properties make it an invaluable resource for businesses seeking to enhance product performance and efficiency. By choosing industrial felt fabric, companies align with a tradition of excellence and innovation, ensuring they remain competitive and responsible within their respective fields.

Next:

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024