1 月 . 15, 2025 09:55

Back to list

felt types

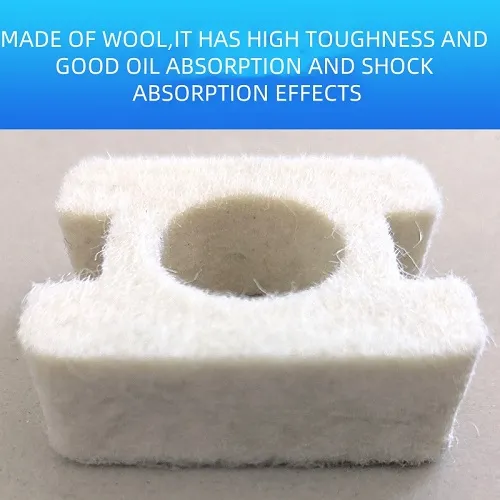

Felt, a versatile and multifaceted material, has become an indispensable resource for numerous industries, from fashion to home decor and industrial applications. Understanding the various types of felt is crucial for choosing the right kind for specific needs and enhancing the performance of products.

Experts in the textile industry often turn to needle-punched synthetic felt for its added strength and uniformity. This process intertwines fibers mechanically, enhancing durability and making it suitable for filtration systems, where reliability is paramount. Trust in synthetic felt's consistent performance has seen its increased adoption in areas requiring precision and stability. Integration of felt types into everyday products is evident in footwear, where comfort is of utmost importance. Wool felt insoles, with their ability to conform to the wearer's foot shape, provide unmatched comfort and support. Meanwhile, synthetic felt is used in the footwear lining for its lightweight and durable nature, exemplifying how both felt types complement each other in product design. The felt industry is ever-evolving, embracing sustainable practices and innovations. Recent advancements in biodegradable synthetic felts are aligning industrial needs with environmental awareness. Felt manufacturers are increasingly prioritizing eco-friendly production techniques, reinforcing the material’s role in sustainable development. For consumers and industry professionals alike, trusting in these enhancements ensures alignment with global environmental and ethical standards. When exploring felt types, it's vital to remember that each type offers distinctive benefits. By leveraging felt's unique properties, industries not only enhance their product offerings but also align them with customer needs and environmental goals. Understanding these subtleties fosters a deeper appreciation and trust in felt, underscoring its relevance today and into the future. As technology and consumer demands evolve, so will felt, continually proving its worth across diverse applications, endorsing its status as a timeless and adaptable material.

Experts in the textile industry often turn to needle-punched synthetic felt for its added strength and uniformity. This process intertwines fibers mechanically, enhancing durability and making it suitable for filtration systems, where reliability is paramount. Trust in synthetic felt's consistent performance has seen its increased adoption in areas requiring precision and stability. Integration of felt types into everyday products is evident in footwear, where comfort is of utmost importance. Wool felt insoles, with their ability to conform to the wearer's foot shape, provide unmatched comfort and support. Meanwhile, synthetic felt is used in the footwear lining for its lightweight and durable nature, exemplifying how both felt types complement each other in product design. The felt industry is ever-evolving, embracing sustainable practices and innovations. Recent advancements in biodegradable synthetic felts are aligning industrial needs with environmental awareness. Felt manufacturers are increasingly prioritizing eco-friendly production techniques, reinforcing the material’s role in sustainable development. For consumers and industry professionals alike, trusting in these enhancements ensures alignment with global environmental and ethical standards. When exploring felt types, it's vital to remember that each type offers distinctive benefits. By leveraging felt's unique properties, industries not only enhance their product offerings but also align them with customer needs and environmental goals. Understanding these subtleties fosters a deeper appreciation and trust in felt, underscoring its relevance today and into the future. As technology and consumer demands evolve, so will felt, continually proving its worth across diverse applications, endorsing its status as a timeless and adaptable material.

Next:

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024