2 月 . 10, 2025 12:39

Back to list

Hotel Towel

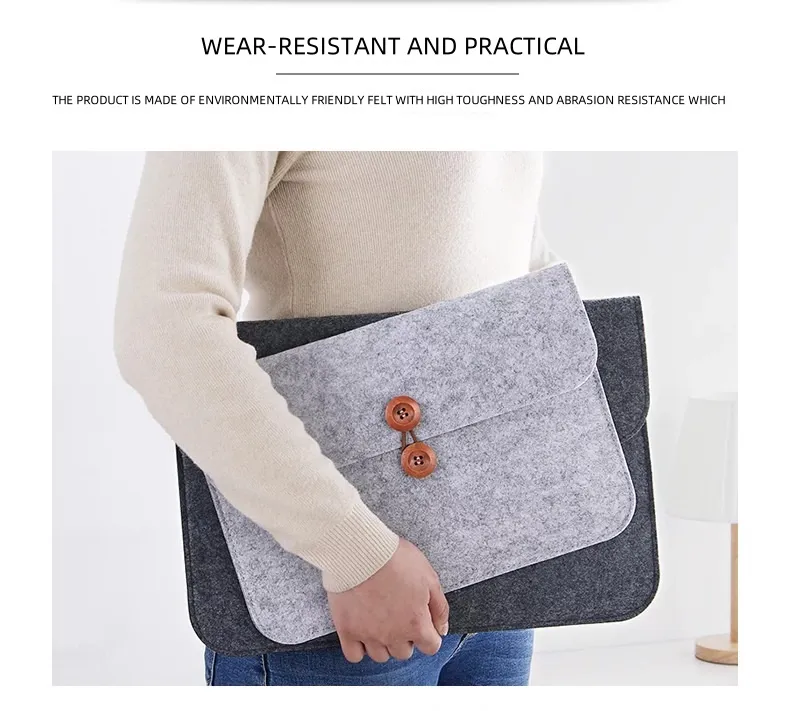

The felt process is a centuries-old craft that has seen a resurgence in recent years thanks to its versatile applications in various industries, from fashion to automotive. This unique process transforms wool fibers into dense, durable fabric without weaving. Understanding the nuances of this process can empower businesses to tap into the competitive edge that felt products provide in terms of sustainability, durability, and aesthetic appeal.

Understanding the different methods of felting—wet felting, needle felting, and industrial felting—is crucial for selecting the right approach for your product. Wet felting, one of the most traditional methods, uses hot water and soap to bind the fibers and is ideal for artisanal pieces. Needle felting employs barbed needles to entangle the fibers mechanically, perfect for detailed work or smaller productions. Industrial felting, on the other hand, which uses advanced machinery for large-scale production, relies on precise settings to reproduce consistent results. Each method requires a deep understanding of both the materials and end use to ensure optimal outcomes. Another important aspect of the felt process is what follows after the felting. This includes treatments such as dyeing, where expertise in color theory can massively affect the attractiveness and marketability of the product. The dyeing process needs careful handling and knowledge of chemical interactions with wool to ensure vibrancy and longevity without compromising the felt’s texture. Expert dye masters can make a product more appealing with colors that enhance the felt’s natural beauty. Also, the environmental impact of the felt-making process can significantly appeal to today’s eco-conscious consumers. Wool is a biodegradable material, and when sourced responsibly, it offers a renewable resource that aligns with sustainable practices. Companies that prioritize eco-friendly methods not only contribute positively to the environment but can also strengthen their market position through the trustworthiness that sustainable practices earn with customers. Thus, the felt process is not just an industrial procedure but a harmonious blend of traditional wisdom and modern practices, honed by generations of artisans and refined by technology. Companies eager to invest in felt products need to prioritize collaboration with experts in the field who can guarantee the quality and authenticity that discerning customers expect. By leveraging experience, expertise, and an unwavering commitment to quality and sustainability, businesses can transform the ancient felt process into a pillar of modern product innovation, achieving not just customer satisfaction but brand loyalty as well.

Understanding the different methods of felting—wet felting, needle felting, and industrial felting—is crucial for selecting the right approach for your product. Wet felting, one of the most traditional methods, uses hot water and soap to bind the fibers and is ideal for artisanal pieces. Needle felting employs barbed needles to entangle the fibers mechanically, perfect for detailed work or smaller productions. Industrial felting, on the other hand, which uses advanced machinery for large-scale production, relies on precise settings to reproduce consistent results. Each method requires a deep understanding of both the materials and end use to ensure optimal outcomes. Another important aspect of the felt process is what follows after the felting. This includes treatments such as dyeing, where expertise in color theory can massively affect the attractiveness and marketability of the product. The dyeing process needs careful handling and knowledge of chemical interactions with wool to ensure vibrancy and longevity without compromising the felt’s texture. Expert dye masters can make a product more appealing with colors that enhance the felt’s natural beauty. Also, the environmental impact of the felt-making process can significantly appeal to today’s eco-conscious consumers. Wool is a biodegradable material, and when sourced responsibly, it offers a renewable resource that aligns with sustainable practices. Companies that prioritize eco-friendly methods not only contribute positively to the environment but can also strengthen their market position through the trustworthiness that sustainable practices earn with customers. Thus, the felt process is not just an industrial procedure but a harmonious blend of traditional wisdom and modern practices, honed by generations of artisans and refined by technology. Companies eager to invest in felt products need to prioritize collaboration with experts in the field who can guarantee the quality and authenticity that discerning customers expect. By leveraging experience, expertise, and an unwavering commitment to quality and sustainability, businesses can transform the ancient felt process into a pillar of modern product innovation, achieving not just customer satisfaction but brand loyalty as well.

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024