1 月 . 15, 2025 10:01

Back to list

robot dog

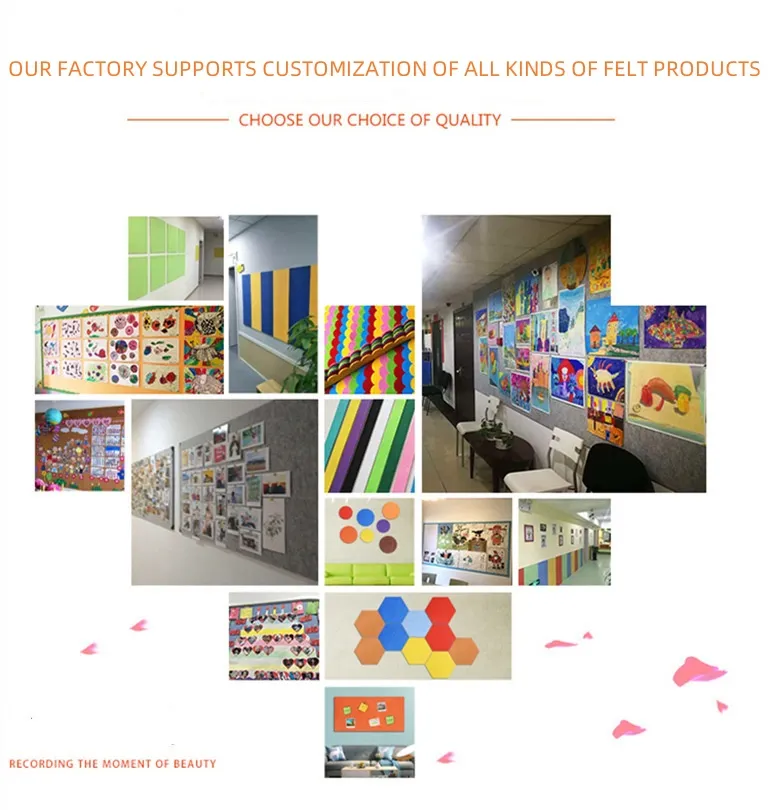

The felt processing industry has experienced a remarkable transformation over the years, capitalizing on its versatility and the inherent benefits of felt as a material. This evolution in the felt process has led to the development of products that are both innovative and essential across various industries. By understanding the depth of this transformation and recognizing the unique attributes of felt, businesses can better position themselves in a competitive marketplace.

Moreover, felt's efficacy in crafting tough yet pliable surfaces transforms it into an ideal candidate for home improvement products. From absorbing vibrations in washers and dryers to providing underlayment for flooring that offers thermal insulation, the felt process ensures these products deliver optimal functionality. These applications highlight felt's adaptability, reflecting its growing importance in creating products that improve daily living conditions. To capitalize on these broad applications, businesses must exhibit expertise and authority in felt processing technology. Leveraging innovation, firms can produce specialized felt materials that meet the increasing demand for performance-oriented solutions. Close collaboration with industry experts in material science further enhances the credibility and trust associated with the brand, reinforcing its reputation as a leader in felt-related products. To establish a trustworthy brand, businesses should focus on transparent sourcing and production methods. As consumers become more environmentally conscious, detailing the lifecycle of felt products—from sourcing raw materials to production techniques—offers reassurance about their sustainability. By building this trust through responsible business practices, companies not only solidify their market position but also advocate for a more sustainable future. The future of the felt process holds infinite possibilities for those willing to embrace the challenges and opportunities of this versatile material. By weaving together innovation, expertise, and a commitment to sustainability, businesses can craft products that not only meet but exceed the expectations of a conscious market. This approach not only secures a competitive edge but also ensures felt remains at the forefront of material technology for years to come.

Moreover, felt's efficacy in crafting tough yet pliable surfaces transforms it into an ideal candidate for home improvement products. From absorbing vibrations in washers and dryers to providing underlayment for flooring that offers thermal insulation, the felt process ensures these products deliver optimal functionality. These applications highlight felt's adaptability, reflecting its growing importance in creating products that improve daily living conditions. To capitalize on these broad applications, businesses must exhibit expertise and authority in felt processing technology. Leveraging innovation, firms can produce specialized felt materials that meet the increasing demand for performance-oriented solutions. Close collaboration with industry experts in material science further enhances the credibility and trust associated with the brand, reinforcing its reputation as a leader in felt-related products. To establish a trustworthy brand, businesses should focus on transparent sourcing and production methods. As consumers become more environmentally conscious, detailing the lifecycle of felt products—from sourcing raw materials to production techniques—offers reassurance about their sustainability. By building this trust through responsible business practices, companies not only solidify their market position but also advocate for a more sustainable future. The future of the felt process holds infinite possibilities for those willing to embrace the challenges and opportunities of this versatile material. By weaving together innovation, expertise, and a commitment to sustainability, businesses can craft products that not only meet but exceed the expectations of a conscious market. This approach not only secures a competitive edge but also ensures felt remains at the forefront of material technology for years to come.

Next:

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024