felt fabric construction

Felt Fabric Construction An Overview

Felt fabric, a versatile and unique textile, has been used for centuries across various cultures. Its construction is relatively simple, yet the resulting material is rich in texture, durability, and functionality. This article explores the intricate process of felt fabric construction, including the types of fibers used, the methods of felting, and the applications of the final product.

Understanding Felt Fabric

Felt is produced by matting, condensing, and pressing fibers together, which can primarily be made from animal hair, wool, or synthetic fibers. Unlike other fabrics that are woven or knitted, felt does not require spinning or weaving. This characteristic makes it a distinct textile, one that can be shaped without fraying or unraveling, a property that is particularly advantageous in crafting and apparel.

Materials Used in Felt Construction

The most traditional felt is made from sheep wool due to its unique scales and elasticity. When wool is subjected to heat, moisture, and agitation, the scales on the fibers catch and interlock, creating a dense matting of fibers. Besides wool, other animal fibers such as alpaca and cashmere can also be used, offering different textures and qualities.

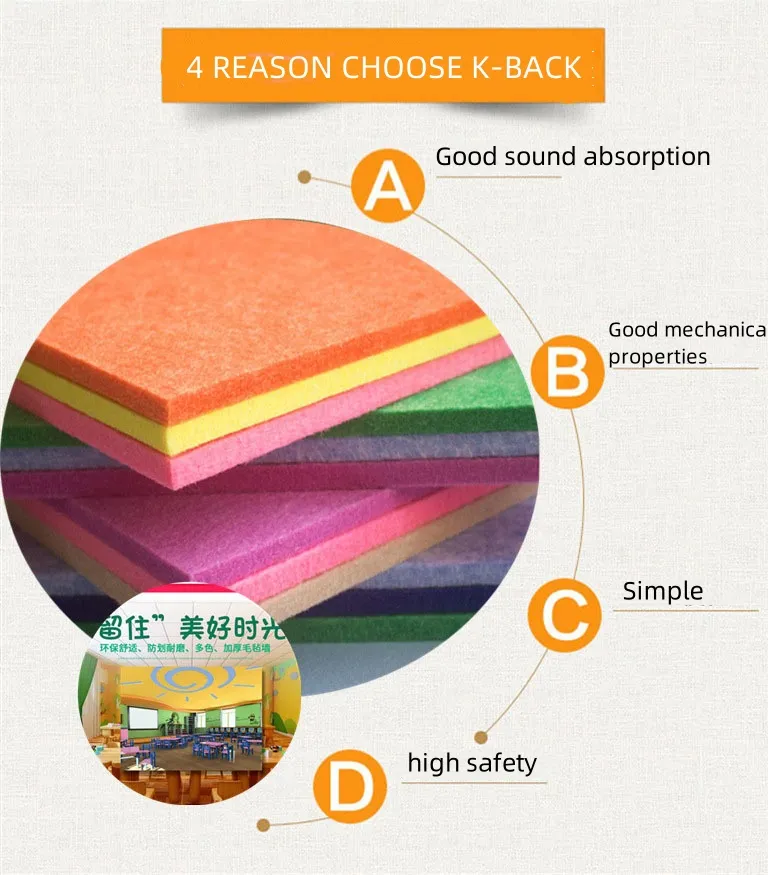

In addition to natural fibers, synthetic materials like acrylic and polyester can also be employed in felt production. These synthetic felts are often more colorful and uniform in texture, making them ideal for craft projects and industrial applications. However, they may lack the breathability and insulation properties of natural wool felt.

The Felting Process

The construction of felt involves three primary methods wet felting, needle felting, and industrial felting.

felt fabric construction

1. Wet Felting This is the most traditional method, where layers of wool fibers are arranged in a crosshatch pattern. Warm soapy water is then applied, and the fibers are agitated through rubbing and rolling. As the fibers become entangled, they start to mat together. The process requires considerable time and effort, but it results in strong, dense felt that preserves the unique characteristics of the wool.

2. Needle Felting In needle felting, barbed needles are used to punch the fibers together. This method does not require water and is often quicker and more controlled than wet felting. Artists commonly use this technique to create detailed designs and sculptures, as it allows for shaping and layering in a more precise manner.

3. Industrial Felting In commercial settings, felt can be produced on a large scale using machinery. The fibers are often carded and then bonded through various methods, including heat and pressure. Industrial felt is widely used in textiles, automotive insulation, and construction materials due to its durability and cost-effectiveness.

Applications of Felt Fabric

Felt’s unique properties lend themselves to a multitude of applications. In the fashion industry, it is used for hats, scarves, and jackets, offering warmth and style. Its sound-dampening qualities make it popular in interior design, especially in the production of wall coverings and flooring.

Additionally, felt is favored in the crafting world for its versatility. Crafters use it for educational toys, embellishments, and home décor items. Felt is also emblematic in cultural artifacts, notably in traditional crafts such as Kazakh yurts and Mongolian boots, showcasing its historical significance.

Conclusion

Felt fabric construction is a fascinating blend of art and science, utilizing simple elements to create a material that is both functional and aesthetically pleasing. With its wide range of applications, felt continues to evolve, finding new roles in contemporary art and design while retaining its historical roots. As we appreciate this unique textile, we are reminded of its enduring place in human creativity and functionality.

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024