2 月 . 19, 2025 09:18

Back to list

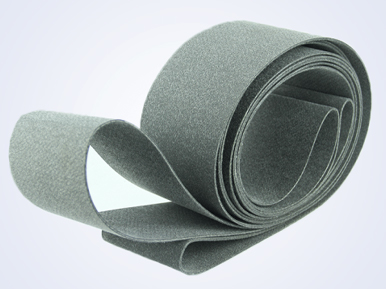

Industrial Oil Absorbing Felt

Automotive felt fabric, an essential component in the modern vehicle industry, has revolutionized the way we perceive functionality and aesthetics in car interiors. Known for its versatile applications, automotive felt fabric stands tall as a testament to the merging of innovation and practicality, making it an indispensable material for manufacturers aiming to elevate the driving experience.

In terms of aesthetics, automotive felt fabric offers a refined finish, which enhances the interior appeal of vehicles. It provides a plush and sophisticated look, transforming car interiors into luxurious spaces. The fabric's texture and color can be personalized, enabling car manufacturers to offer bespoke interiors that reflect the tastes and preferences of contemporary consumers. Trustworthiness and reliability are cornerstone attributes associated with automotive felt fabric. Its consistent performance across various environmental conditions assures manufacturers and consumers alike of its dependability. Automotive companies rely on this material to uphold their stringent quality standards and deliver products that inspire consumer confidence. The industry expertise surrounding automotive felt fabric is backed by rigorous research and development. Leading manufacturers continuously innovate to improve and expand its applications, ensuring that automotive felt fabric remains at the forefront of vehicular advancements. The ongoing collaboration between material scientists and automotive engineers exemplifies the authoritative strides taken to enhance its effectiveness. In conclusion, automotive felt fabric is more than just a component; it is a catalyst for innovation and improvement in the automotive industry. Its unparalleled blend of sound insulation, durability, adaptability, and aesthetics sets it apart as a material of choice for automakers worldwide. With a commitment to sustainability and quality, automotive felt fabric continues to shape the future of vehicle design, offering consumers an unrivaled driving experience that marries comfort, elegance, and environmental responsibility.

In terms of aesthetics, automotive felt fabric offers a refined finish, which enhances the interior appeal of vehicles. It provides a plush and sophisticated look, transforming car interiors into luxurious spaces. The fabric's texture and color can be personalized, enabling car manufacturers to offer bespoke interiors that reflect the tastes and preferences of contemporary consumers. Trustworthiness and reliability are cornerstone attributes associated with automotive felt fabric. Its consistent performance across various environmental conditions assures manufacturers and consumers alike of its dependability. Automotive companies rely on this material to uphold their stringent quality standards and deliver products that inspire consumer confidence. The industry expertise surrounding automotive felt fabric is backed by rigorous research and development. Leading manufacturers continuously innovate to improve and expand its applications, ensuring that automotive felt fabric remains at the forefront of vehicular advancements. The ongoing collaboration between material scientists and automotive engineers exemplifies the authoritative strides taken to enhance its effectiveness. In conclusion, automotive felt fabric is more than just a component; it is a catalyst for innovation and improvement in the automotive industry. Its unparalleled blend of sound insulation, durability, adaptability, and aesthetics sets it apart as a material of choice for automakers worldwide. With a commitment to sustainability and quality, automotive felt fabric continues to shape the future of vehicle design, offering consumers an unrivaled driving experience that marries comfort, elegance, and environmental responsibility.

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024