1 月 . 21, 2025 04:56

Back to list

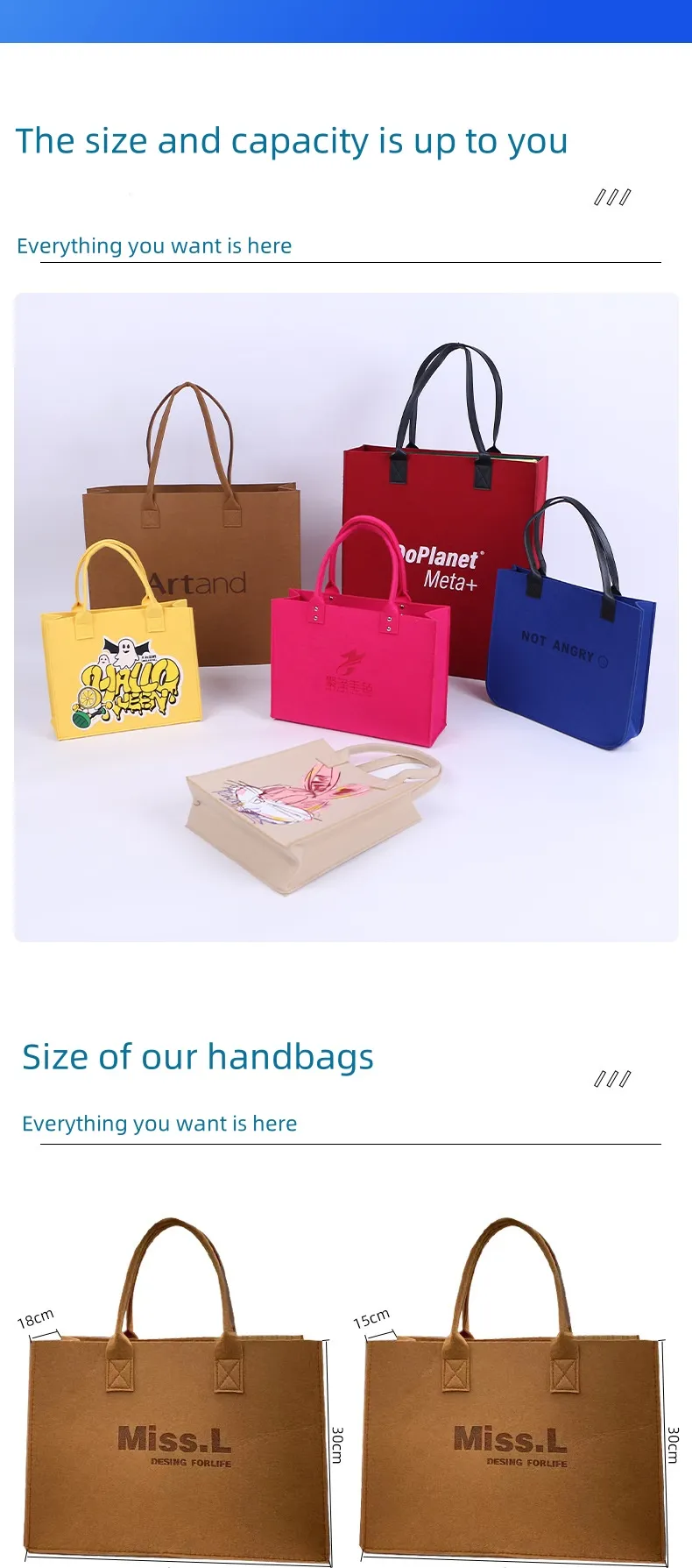

Customized Logo Foldable Felt Storage Bins With Handles

The world of polishing tasks has seen substantial evolution over the years, but the felt polishing wheel remains a timeless tool esteemed for its efficiency and versatility. This indispensable tool is favored by professionals and DIY enthusiasts alike, thanks to its ability to deliver a superior finish on a wide array of materials. Delving into the intricacies of the felt polishing wheel not only reveals its practicality but also its indispensable role in achieving flawless finishes across industries.

Beyond functionality, the authority of felt polishing wheels is further validated by their long-standing endorsement within established industries. Jewelers, for example, rely on felt wheels not only for finishing precious metals but also for refining gemstones, highlighting their universal appeal. Similarly, automotive shops utilize felt polishing wheels to restore headlights and remove oxidation from vehicle surfaces, demonstrating their importance in maintaining both aesthetic and functional standards. Trustworthiness in polishing tasks is paramount, and felt polishing wheels excel in delivering consistent results. Precision is critical when working on high-value items, and these wheels provide the control and reliability craftsmen require to meet high-quality standards repeatedly. Their construction, typically devoid of abrasive grains, minimizes the risk of damaging surfaces, ensuring peace of mind for users engaged in delicate projects. Embracing new developments, many manufacturers are innovating the felt polishing wheel design, optimizing fiber mixes and densities to enhance performance further. These advancements continue to affirm the material's standing in the polishing domain, cementing it as a staple in workshops and studios worldwide. Users benefit not just from the legacy of felt polishing tools but from ongoing improvements that refine their efficiency and adaptability. In conclusion, the felt polishing wheel's broad application range, adaptability, and proven durability make it an indispensable asset for anyone involved in surface finishing tasks. Its longstanding reputation as a reliable tool endears it to seasoned professionals and hobbyists alike. Armed with the knowledge of selecting the appropriate wheel characteristics for specific tasks, users can easily achieve remarkable polishing results. Whether enhancing the brilliance of fine jewelry or restoring the sheen on automotive components, the felt polishing wheel remains a trusted ally in the pursuit of perfection.

Beyond functionality, the authority of felt polishing wheels is further validated by their long-standing endorsement within established industries. Jewelers, for example, rely on felt wheels not only for finishing precious metals but also for refining gemstones, highlighting their universal appeal. Similarly, automotive shops utilize felt polishing wheels to restore headlights and remove oxidation from vehicle surfaces, demonstrating their importance in maintaining both aesthetic and functional standards. Trustworthiness in polishing tasks is paramount, and felt polishing wheels excel in delivering consistent results. Precision is critical when working on high-value items, and these wheels provide the control and reliability craftsmen require to meet high-quality standards repeatedly. Their construction, typically devoid of abrasive grains, minimizes the risk of damaging surfaces, ensuring peace of mind for users engaged in delicate projects. Embracing new developments, many manufacturers are innovating the felt polishing wheel design, optimizing fiber mixes and densities to enhance performance further. These advancements continue to affirm the material's standing in the polishing domain, cementing it as a staple in workshops and studios worldwide. Users benefit not just from the legacy of felt polishing tools but from ongoing improvements that refine their efficiency and adaptability. In conclusion, the felt polishing wheel's broad application range, adaptability, and proven durability make it an indispensable asset for anyone involved in surface finishing tasks. Its longstanding reputation as a reliable tool endears it to seasoned professionals and hobbyists alike. Armed with the knowledge of selecting the appropriate wheel characteristics for specific tasks, users can easily achieve remarkable polishing results. Whether enhancing the brilliance of fine jewelry or restoring the sheen on automotive components, the felt polishing wheel remains a trusted ally in the pursuit of perfection.

Latest news

-

Your Go-To Guide For Affordable Wholesale Wool FeltNewsOct.31,2024

-

The Trusted Source For Industrial Felt And Hotel TowelsNewsOct.31,2024

-

Premium Industrial Felt Solutions For Every IndustryNewsOct.31,2024

-

Enhancing Performance With Industrial Felt FabricsNewsOct.31,2024

-

Elevating Performance With High-Quality Industrial Felt MaterialsNewsOct.31,2024

-

Brighten Your Projects With Vibrant Colored FeltNewsOct.31,2024

-

Unleash Your Creativity with Stylish Felt ProductsNewsOct.30,2024